Custom vibration-damping solutions that reduce vibration, structure-borne noise, and shock—designed for reliable machines, accurate measurements, and quieter facilities.

Our high-quality anti-vibration mats and pads for industry, infrastructure, buildings as well as labs are tailored to your load, footprint, and environment—improving safety, extending equipment life, and protecting floors and foundations. We export our custom anti-vibration solutions globally.

Anti-Vibration Mats & Pads for Industry, Infrastructure, Buildings, and Labs

Anti-Vibration Mats & Pads for Industry, Infrastructure, Buildings, and Labs

Quick quote:

- Provide required information to us

- Email it to us: info@antivibrationsmatten.com

- Get offer from us

Information Required for an Offer

1. Application Details

- Type of machine or installation (e.g., compressor, CNC machine, pump, laboratory device)

- Purpose of damping (e.g., reduce vibration, prevent structure-borne noise, improve measurement accuracy)

- Indoor or outdoor use

- Ideally pictures or simple drawing

2. Load Data

- Total weight of the machine or equipment (in kg or tons)

- Number and position of support points (feet, base frame, etc.)

- Surface area or footprint of each support point (mm × mm)

- Estimated dynamic load (if applicable: frequency, amplitude, rpm, or stroke)

3. Vibration Characteristics

- Type of vibration: rotating, impact, pulsing, oscillating, etc.

- Operating frequency or speed (Hz or rpm)

- Required isolation level or target (e.g., percentage vibration reduction, noise reduction in dB)

4. Environmental Conditions

- Temperature range

- Exposure to oils, fuels, chemicals, moisture, or UV radiation

- Installation surface (concrete, steel frame, floor tiles, etc.)

5. Product Preferences

- Any special requirements (fire resistance, hygiene, color, certifications)

6. Contact & Logistics

- Company name and contact person

- Address and delivery location

- Phone and email

- Desired delivery date or project deadline

Why Anti-Vibration Mats or Pads?

- Reduce vibration & secondary noise (structure-borne sound) at the source to protect staff, neighbors, and structures.

- Extend equipment lifetime by cutting wear on bearings, frames, and foundations.

- Improve measurement accuracy for sensitive instruments.

- Low-effort installation—often no fixings required; mats can be cut to fit.

How to Choose the Right Mat

- Machine weight & load footprint (kN/m²)

- Vibration type & frequency (rotating vs. impact, low-frequency isolation needs)

- Environment (oils/chemicals, indoor/outdoor, temperature, moisture/UV)

- Target outcomes (noise reduction, displacement limits, measurement precision)

We provide tailored sizing, hardness (Shore), thickness (typically 5–50 mm), and cut-to-fit plates or pads to meet your specification.

Typical Applications in Industries

Manufacturing & Processing

Place mats or pads beneath CNC machines, mills, presses, shears, mixers, vibratory feeders, pumps, compressors, and dosing stations to reduce transmission into floors and adjacent lines, lowering maintenance and downtime.

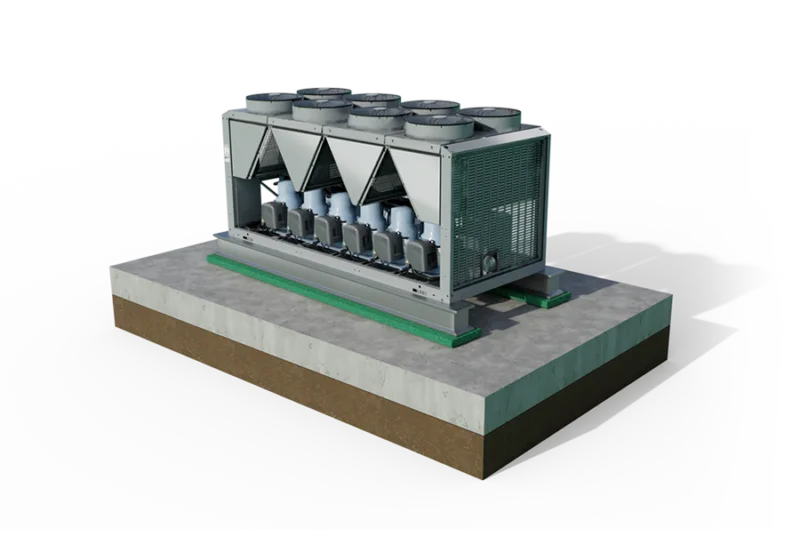

Energy, HVAC & Utilities

Damp vibrations from transformers, generators, heat pumps, and large air-handling units—supporting system stability and reducing secondary noise. Weather-resistant variants available.

Rail & Transportation

Support smoother operations and reduced noise in rail lines, tunnels, rolling stock, and stations with vibration-damping elastomer solutions.

Marine & Offshore

Protect ship engines and generators from wave- and wind-induced shocks and allow controlled movement in structural bearings—reliable performance even at very low temperatures.

Buildings, Civil & Infrastructure

Use mats for foundation isolation, elevator shafts, plant rooms, bridges, tunnels, pools, and impact-sound reduction in floors and walls—cutting structure-borne noise and vibration pathways through concrete and steel.

For Precision Environments: Labs & Research

Anti-vibration solutions are used in laboratories across industries such as pharmaceuticals, biotechnology, metrology, semiconductors, and research institutions as well as universities.

Even tiny vibrations can blur images or distort measurements. For microscopes, analytical balances, spectrometers, chromatographs, coordinate-measuring machines, roughness testers, SEM/TEM, incubator-shakers, cryostats, and other precision setups, we offer:

- High-mass granite plates supported by tuned elastomer elements

- Anti-vibration tables and low-eigenfrequency pads for lightweight instruments

- Options for medical devices and particle counters where stable baselines are critical

We supply numerous research institutes, universities, and technical laboratories.

Materials & Buildings

- Recycled rubber granulate or engineered elastomers (NR/SBR/NBR, PUR) for load-bearing damping with durability and sustainability benefits.

- Optional oil-, ozone-, and UV-resistant compounds for harsh environments.

FAQs

What are anti-vibration mats or pads?

Elastic mats or pads that absorb and isolate vibration and shock, protecting machines, floors, and structures while reducing noise.

Where are they used?

Under machines, pumps, compressors, transformers, HVAC units, laboratory instruments, and building foundations—anywhere vibration needs damping or isolation.

How are they installed?

Often laid directly under equipment with even load distribution; multiple plates can be cut and positioned for large bases—usually no anchors required.

Are there different thicknesses and sizes?

Yes—custom cuts and typical thicknesses from 5 mm to 50 mm. Heavier machinery often uses thicker mats or multi-layer stacks.

What alternatives exist for heavy or low-frequency isolation?

Elastomer pads, spring or air isolators, inertia bases (mass platforms), and active systems for ultra-precision setups.