Anti-vibration mats and pads for industry, machinery, measuring devices, compressors, cooling units, generators, pumps, buildings, construction, rails, test beds, shakers etc.

In addition to industrial customers including the pharmaceutical industry, we supply our customized antivibration solutions also to renowned (technical) universities, laboratories and research institutes.

Customized antivibration solutions

for industry, machinery and construction

What are anti-vibration mats?

Vibrations can occur in many different types of industrial environments. They often come from the various machines and equipment found in such areas. The steady rhythm of vibrations can be a real nuisance to employees. However, such vibrations can sometimes go beyond a mere nuisance, affecting both the machinery and the floor below, as well as the health of employees. Thanks to the sound-absorbing properties of rubber, anti-vibration mats can make an industrial workplace more pleasant by absorbing noise from vibrations and reducing noise levels in the area. Anti-vibration mats are therefore very important in minimizing vibrations from industrial machinery.

Where are indusrial anti-vibrations mats used?

Anti-vibration mats and pads are essential for a variety of industrial and commercial applications, including machinery, compressors, cooling units, generators, pumps, and more. They are also commonly used in building and construction, as well as on rails and other types of transportation infrastructure. These specialized mats and pads are designed to reduce vibration and noise levels, improving safety and comfort for workers and reducing the risk of damage to equipment.

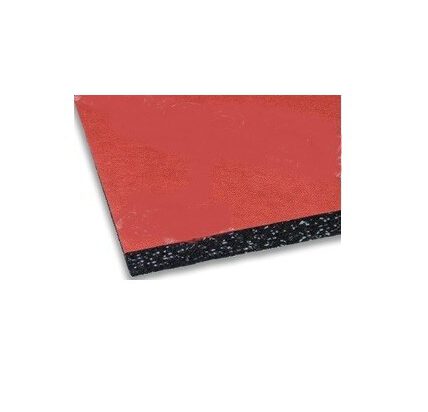

From what materials anti-vibration mats and pads are made?

Anti-vibrations mats and pass are made from durable plastic and rubber materials that can withstand heavy loads and harsh conditions, making them a reliable choice for a wide range of applications. Whether you are looking to reduce vibration and noise in a busy factory, protect sensitive equipment in a laboratory, or improve the comfort and safety of your workplace, anti-vibration mats and pads can be a valuable investment. Anti-vibration mats can be used to shield / isolate industrial machinery from direct contact with solid floors. Vibrations, especially those emanating from heavy industrial machinery, can cause severe damage to both the floors of an area and the machinery itself from which they emanate. Anti-vibration mats / anti-vibration mats can be used to protect industrial floors and employees from highly vibrating machines. Anti-vibration mats made of rubber / elastomers are elastic enough to absorb shocks and at the same time resistant enough to withstand the strongest loads, e.g. those of high-speed trains built into the track body.

Typical applications for vibration damping mats and pads include

Anti-vibration mats and pads can be used in various applications and machines in industries, buildings, and transportation, including:

- Agitators

- Air intake, for example in baking ovens

- Bale presses

- CNC milling machines

- Compressors

- Crushers, pre-crushers, granulators, shredders, and other equipment

- Crushing machines and garbage presses, e.g., for recycling

- Die hammers

- Dosing stations / dosing systems

- Embossing presses

- Forging hammers

- Frames for robots

- Generators

- Heavy machine tools

- Hydraulic equipment / hydraulic presses and other hydraulic systems

- Injection molding machines

- Jaw crushers

- Mills, including ball mills, hammer mills, rotor mills, cutting mills, knife mills, mortar mills, and disc mills

- Mixers

- Power transformers

- Presses, stamping presses

- Pumps, heat pumps, air compressors, and hydraulic pumps

- Punching machines / punch presses / automatic punch presses

- Punching machines, stamping presses, stamping machines

- Robots

- Screening machines

- Server rooms (reduction of noise from servers)

- Sieving machines

- Stainless steel swimming pools (noise reduction of splashing sounds)

- Test benches for cars, etc.

- Transformers (resistant to transformer oil)

- Transport carts / truck trailers

- Transport trolleys / truck trailers

- Vibrating conveyors

- Vibrating systems

- Vibration and noise damping of rails installed in the track body (e.g. for high-speed trains, subways, streetcars)

- Vibration damping foundations for machines

- Wooden floors / hardwood floors (noise reduction)

Heavy machinery that vibrates during use is abrasive by nature. They are often made of hard materials, such as steel, and can weigh up to several tons. It doesn’t help that they are often placed on equally hard and unforgiving surfaces without padded mats for protection. The most common types of industrial flooring are asphalt and concrete, which cannot absorb the shocks and impacts of modern machinery.